Submitted ByEdit Dates

Date Uploaded: August 5, 2004, 3:04 pm Last Edited: January 31, 2016, 2:07 am |

Riveted Maille Tools: Cutters

Article Tags[ Cutting Rings ] [ Riveted Maille ] [ Tool Modification ] [ Tools ] |

Add to Add toSite Favourites Print this Article |

Riveted Maille Tools: Cutters

Article © MAIL User: Eli

Making cutters that cut pre-overlapped rings is the easiest modification of the riveted maille tools. All that needs to be done is to cut or grind a groove behind the cutting point that will accommodate for the overlapped region of the ring. The easiest way to make the groove is by a diamond coated file because it’s fast and non-destructive (it won’t remove the temper on the cutting jaws). A dremel may be used for this also, although I haven’t tried it myself.

Since writing this article I managed to ruin the alignment on the bolt cutters by cutting thousands of 2mm rings, so I further modified my old pair of side-cutters to increase leverage and reduce strain. I now use the modified side cutters with great success.

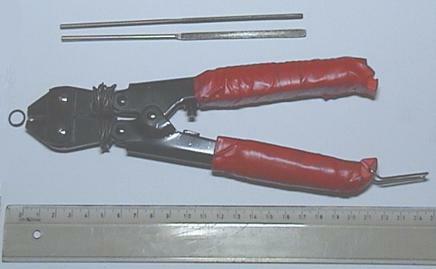

I ground the cutting jaws almost to the axis, leaving only about a centimeter sticking out. In order for the tip to fit into the coil I ground the lower jaw on a bench grinder as shown in the picture. Once done I made the grooves again to skip the overlap, much as with the bolt-cutters. The handles are wrapped with a thick layer of cloth taken from an old T-shirt, held together with electric tape and sticky paper.

The cutters best suitable for this job are mini-bolt cutters. They give you ample leverage to easily deal with steel wire, have enough metal in their jaws to reduce the risk of breaking and are readily available and cheap. Here you can see the pair of mini-bolt cutters I modified and use for cutting 1.3mm tie wire. The groove has been cut using the two files shown in the picture (triangular and flat). The tip of the cutters has been ground with a bench grinder to make it in a 90 degree angle. The wire wrapped around the middle section prevents the cutters to open all the way. I’ve done this because fighting the spring to close the cutters was a waste of time and energy. Now the cutters open to about twice the wire thickness. The handles are covered in a length of cloth from an old T-shirt secured by electric insulator tape.

One can also use side cutters. The main problem with them is the lack of leverage, making it much more tiring to cut large amounts of rings. As I have shown above, this can be fixed. This pair I used to cut my normal butted 1mm galvanized steel. After awhile the tip broke about 1cm from the end, so now it has more metal at the tip. When I started making riveted maille with copper I used this pair, which worked quite well. When I tried them on steel they proved inadequate.

Original URL: http://www.mailleartisans.org/articles/articledisplay.php?key=220